Test Capabilities

- Battery Test

- ECU Test

- Camera assembly test

- HiL Test

- EV Testing

- Sensor Validation Test

- Sensor Production Test

- Object Simulation

- ADAS XiL

- ADAS Record & Replay

KT-RAPTER

The Konrad Technologies Radar Production Test System (KT-RAPTER) is a versatile, stand-alone radar test system that complies with safety regulations and offers customizable instrumentation and mechatronic controls. It is specifically designed to address the evolving requirements of autonomous driving regulations, catering to the complex testing needs for both radar sensor production and design verification. The KT-RAPTER is production-ready and adheres to more than 12 manufacturing safety standards, allowing manufacturers to tailor radar sensor test plans to their needs, ultimately enhancing test yield and quality.

Automotive Battery Test

Konrad Technologies collaborated closely with one of the largest US automotive OEMs to design and construct multiple battery cell open circuit voltage (OCV) monitoring systems. These cutting-edge systems enable long-term monitoring of over 1000 prismatic and pouch cells distributed across fourteen environmental chambers.

Our OCV monitoring system performs a ten-second measurement on each cell daily, capturing data at a sampling rate of 1 Hz. The recorded measurement values are automatically logged and compared against predefined limits. A customized graphical user interface (GUI) highlights any cells that fall outside the specified limits, alerting staff to take any necessary actions.

To minimize discharge, the system intelligently disconnects the cells from the PXI DMM in between measurements. Additionally, the temperature within each incubator is carefully monitored, tiggering alarms if preset limits are exceeded. This ensures optimal testing conditions and provides immediate visibility into any deviations

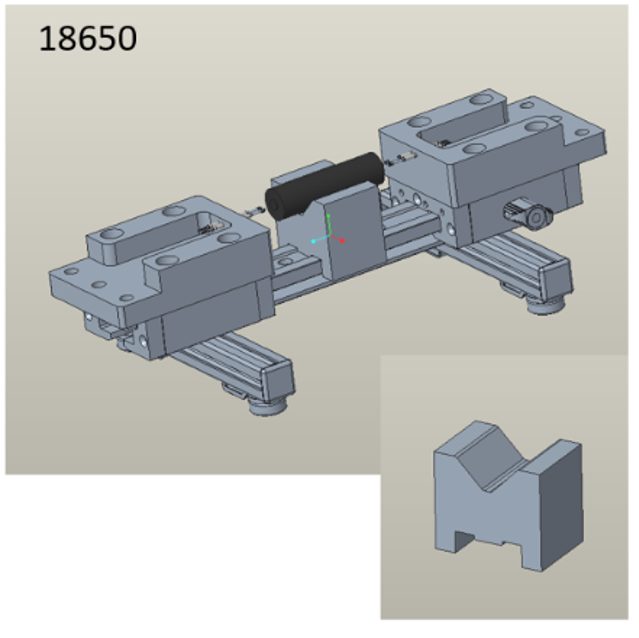

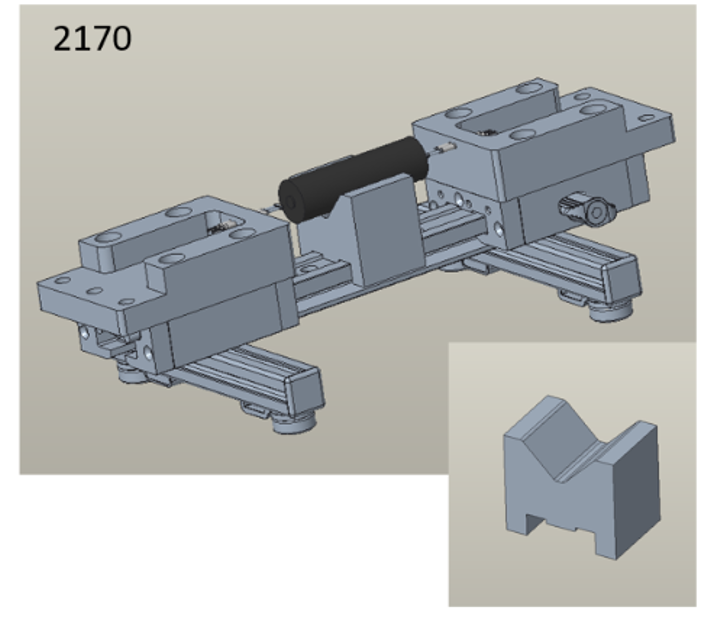

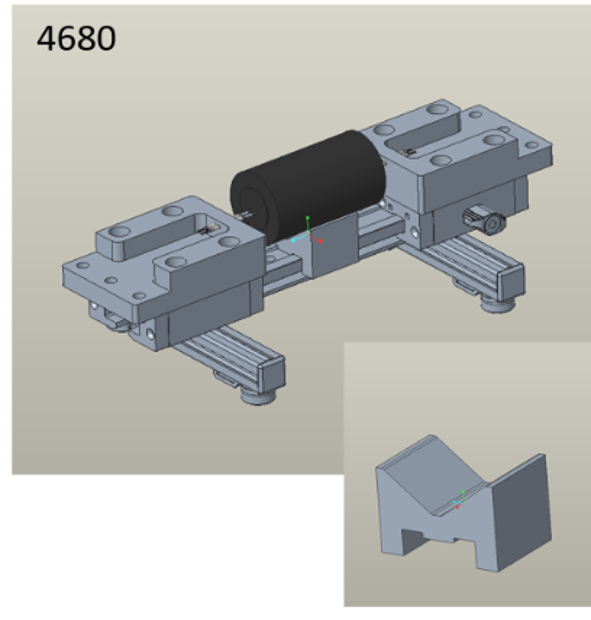

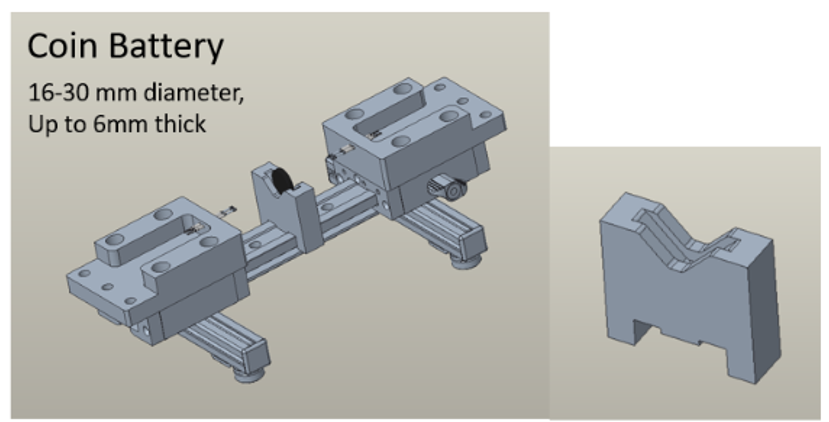

Battery Cell Quality Fixtures

ECU Test

Electrical Fault Test

Whether your team is working on a new product or testing components of existing systems, your goal is to complete your testing cycles quickly while ensuring high degree of accuracy. Traditional testing methods often require manual work, waste valuable time, and increase your time to market, making your department the bottleneck of the development process.

That’s why Konrad Technologies has partnered with WKS Informatik to bring the first fully automated electrical fault testing system to the Americas. RTStand automates test execution, data logging, and reporting by eliminating manual tasks. Any electrical component in a vehicle can be tested on one common platform.

Camera Interfacing

KT-CAMULATOR Camera Direct Injection Solution

KT-CAMULATOR serves as a data bridge from virtual simulators to an Electronic Control Unit (ECU) while emulating the authentic behavior of a camera. Using the KT-CAMULATOR, test engineers can effectively validate a wide range of camera-based ADAS/AD systems. The solution supports up to 16 HDMI inputs with simultaneous emulation of multiple camera data streams, where users can easily configure and synchronize multiple cameras.

MdynamiX Solutions for Steering HiL

Konrad Technologies is the exclusive US partner for MdynamiX, delivering steering test solutions for manual, assisted, and automated driving applications.

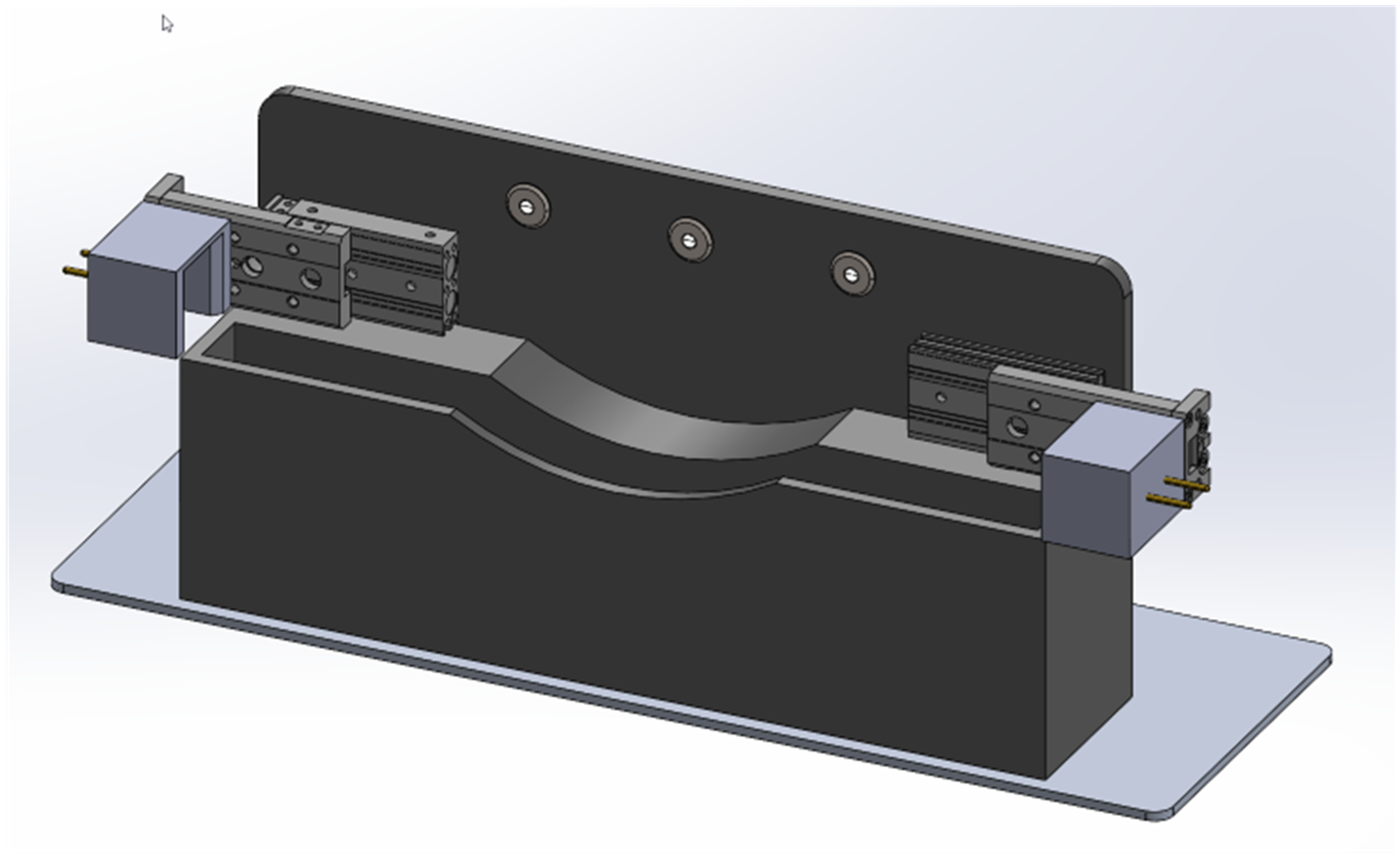

MXsteerHiL mini test bench allows a fully comprehensive test setup of rack assist EPS system with no compromise to performance. With a force of max. 16 kN and a velocity of 300 mm/s, the bench covers nearly all common steering tests while having small footprint of just 1200 x 800 mm.

.

Key Features:

- suitable for all types of steering racks

- actuation via electric linear spindle and a rotational motor (27 Nm) at the spindle

- HiL compatibility via MXsteerCon with any real-time system

- model-based control strategy for real-time applications

- deterministic real-time connection with EtherCAT

MXsteerWheel RTpro is a high performance force feedback unit for engineers of steering systems and ADAS/AD development with the focus on the steering feel. It provides a realistic and comprehensive simulation of a steering wheel’s behavior with real-time feedback and results before accessing any physical hardware.

Key Features:

- achieve realistic haptic results through simulation

- smooth and stable running of complex steering model

- perfect tool for development of steering feel and additional steering functions

- implementation of parameter sets from real measured steering systems

- deterministic real-time-connection with EtherCAT