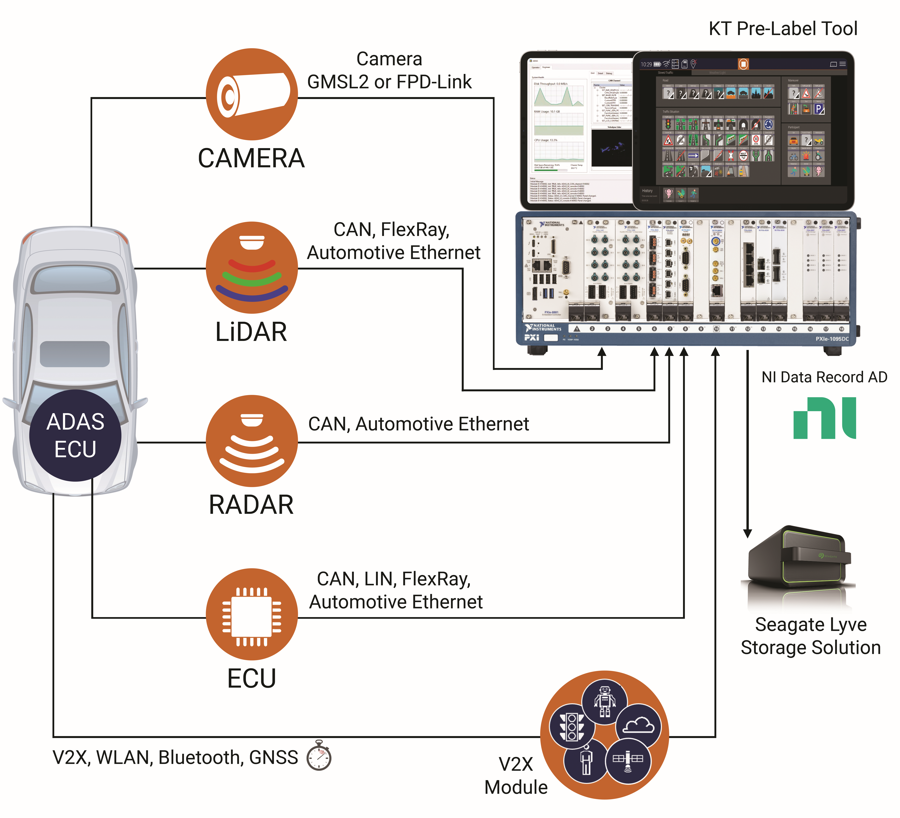

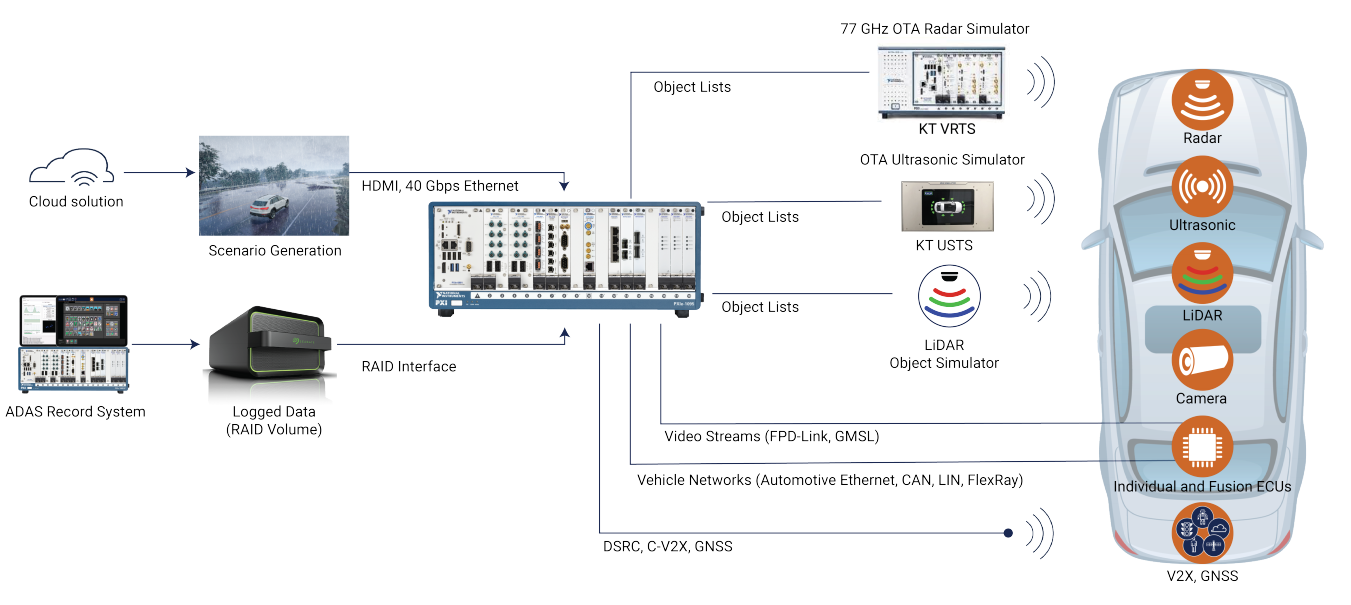

Konrad Technologies partnered with NI and Seagate to create the ADAS Record system that captures raw sensor data, object data, other automotive network traffic, and relevant metadata to disk with hardware-timed synchronization. These data can then be uploaded to an on-prem or hosted cloud for subsequent analysis, and/or used as test scenarios in the lab for data replay via direct injection into an ADAS ECU in an XiL system.

This ADAS Record System combines NI PXIe instrumentation, Seagate storage, and the NI/Konrad Data Record AD software. Konrad Technologies’ Pre-Label Tool allows the user to collect and label the metadata during a drive test for a post event analysis. The user can pick from a library of more than 150 event labels or create custom labels and fields to locate specific data quickly.

Configurations and drive scenarios can be stored and reused.