- PCBA Test Systems

- Component Test Systems

- RF Test Systems

- Device Level Test Systems

- Battery Test

- Pump / Valve Test Systems

- Manufacturing Test

- Final Functional Test

- Production Test

- Digital Board Test

- Programming Stations

- V&V

- System Automation

LEONBench

LEONBench is a standalone bench test system for FCT, ICT, ISP and Boundary Scan with support for manual and vacuum fixtures.

It’s a flexible and scalable test system that features an excellent signal integrity and a high-quality fixture interface. This is achieved by combining a cableless connection from ABex modules to Virginia panel interface connectors. The system is optimized for high pin count test applications. Furthermore, it can be equipped with vacuum and pneumatic handling. Support for multi-level contact fixtures enables separate contact levels for FCT and ICT. The Konrad ITA (Interchangeable Test Adapter) frame allows various fixture houses to build custom fixtures for the LEONBench. Additional rack space (up to 15 units) allows addition of high-performance measurement devices from various manufacturers. An integrated power distribution unit provides power on and off sequencing.

As part of the LEON Family, LEONBench is based on the ABex platform which directly incorporates Konrad analog bus technology and PXI/PXIe in one chassis.

Battery Test

Konrad Technologies designed and developed a PXI-based data

acquisition and control system for performing electrical tests on

button cell batteries. It would be equally relevant to other small

primary batteries.

This 100-up parallel battery tester applies constant current load levels for fixed time intervals while recording battery output voltage and current. The system applies predefined sequences of loads and measurements to all batteries in parallel, but it can turn off each cell individually after it reaches a configurable limit.

After the system was delivered, Konrad continued to work with the

client and provided multiple upgrades and improvements such as

updated software functionality to allow removal of individual loads

after specified conditions are met.

Camera Interfacing

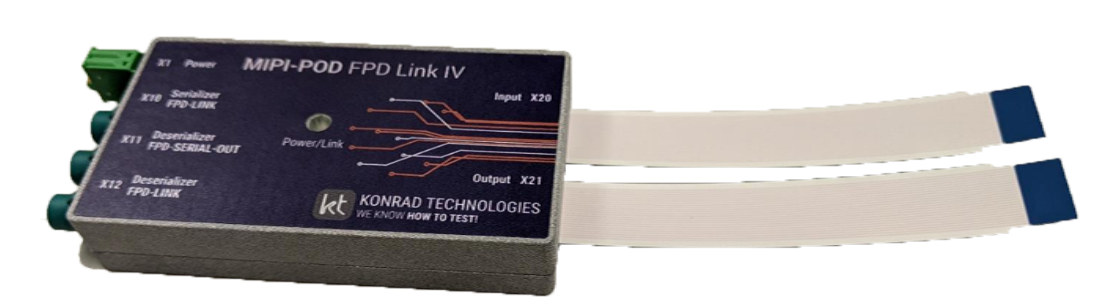

KT MIPI Pod

The MIPI POD provides an FPD-LINK IV serializer and deserializer pair to transform data from MIPI CSI-2 to FPD-LINK IV and from FPD-LINK IV to MIPI CSI-2. Both the serializer and deserializer have input and output FAKRA and FFC (Flexible Flat Cable) connections. The MIPI POD can be powered externally or via PoC (Power over Coax).