- Production test

- Power rail test

- RF test

- Final Functional Test

- Digital Board Test

- Manufacturing test

- PCBA Test Systems

- Component Test Systems

- Programming Stations

- RF Test Systems (BLE, Wi-Fi, 5G, OTA)

- V&V (IQ, OQ, PQ)

- Battery Test

- Pump/Valve Test Systems

- Device Level Test Systems (IPGs, ICDs, meters)

- Automation: DUT/Sample Thermal Control; DUT/Sample Handling

- RF Standards Based Testing

LEONBench

LEONBench is a standalone bench test system for FCT, ICT, ISP and Boundary Scan with support for manual and vacuum fixtures.

It’s a flexible and scalable test system that features an excellent signal integrity and a high-quality fixture interface. This is achieved by combining a cableless connection from ABex modules to Virginia panel interface connectors. The system is optimized for high pin count test applications. Furthermore, it can be equipped with vacuum and pneumatic handling. Support for multi-level contact fixtures enables separate contact levels for FCT and ICT. The Konrad ITA (Interchangeable Test Adapter) frame allows various fixture houses to build custom fixtures for the LEONBench. Additional rack space (up to 15 units) allows addition of high-performance measurement devices from various manufacturers. An integrated power distribution unit provides power on and off sequencing.

As part of the LEON Family, LEONBench is based on the ABex platform which directly incorporates Konrad analog bus technology and PXI/PXIe in one chassis.

Battery Test

Konrad’s Battery Quality Test Capabilities

- The KT Cell Quality platform is based on the PXI modular instrumentation platform.

- Precision measurements achieved via calibration procedure regardless of signal routing and custom fixturing.

- Best-in-class measurement resolution and accuracy

- Solution is well-suited for large cells with a capacity over 140 amp-hours (some competitors will struggle with larger cell sizes).

- LabVIEW provides a completely software-defined test system capability. Data can be acquired, analyzed, and presented exactly to customer specifications. User experience and workflow are matched exactly to customer requirements.

Camera Interfacing

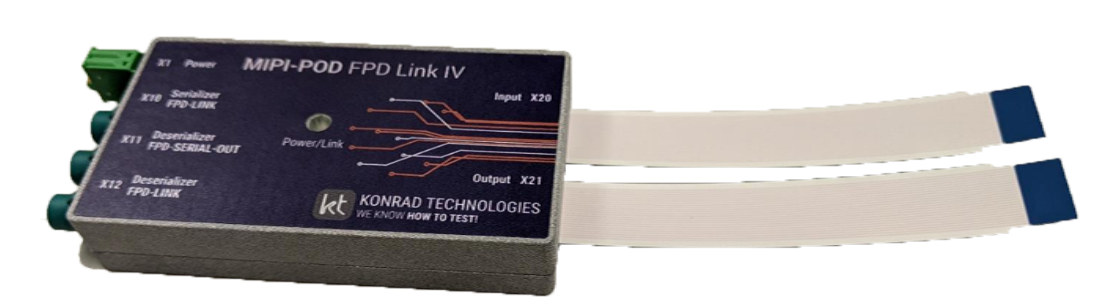

KT MIPI Pod

The MIPI POD provides an FPD-LINK IV serializer and deserializer pair to transform data from MIPI CSI-2 to FPD-LINK IV and from FPD-LINK IV to MIPI CSI-2. Both the serializer and deserializer have input and output FAKRA and FFC (Flexible Flat Cable) connections. The MIPI POD can be powered externally or via PoC (Power over Coax).

Project Example: Xbox 360 Controller Production Test System

Konrad Technologies designed and built a solution that tests the trigger buttons, push buttons, and cable connections of both wired and wireless Xbox game controllers. This production test system monitors signals at the chip level to analyze the electrical signals for parameters such as rise/fall times, minimum/maximum voltage levels, and current draw. Device communication test and data packets are also monitored at the bit level to verify that all controller-functional messages are within specification. The system supports more than 100 tests, implements Ethernet communication, and incorporates a data storage interface to the Microsoft SQL Server database.